The ANTECH G3107-1000 Soil Measuring and Segregation System is a mobile assay system for the bulk measurement and segregation of soil or rubble with radiological contamination from uncontaminated soil or rubble. Based on a large volume, high efficiency Sodium Iodide detector positioned over rugged feed through conveyors, the G3107 is designed for rapid on-site assessment with high volume throughput.

- High throughput for rapid segregation.

- Self contained, mobile system for in-field deployment and operation.

Benefits

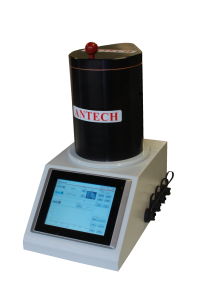

- Large volume, high efficiency Sodium Iodide (NaI(Tl)) LRGS detector.

- Shielded detector housing with lead and tin liners to reduce background radiation.

- Variable speed throughput conveyor.

- 2 or 3 way sample segregation based on configurable limits.

- Soil moisture content correction and sample material

Features

-

Description

The G3107 is a self-contained measuring and segregation unit that can be used in conjunction with a radiological survey to sort or segregate all potentially contaminated soil at a given site. This makes it possible to isolate soil contaminated above the assessed reporting level and to return uncontaminated soil to the site as landfill. Despite the costs of soil handling and soil monitoring, the Soil Measuring and Segregation System (SMSS) enables significant cost savings to be made by minimising the quantity of contaminated soil that must be shipped off-site for disposal.

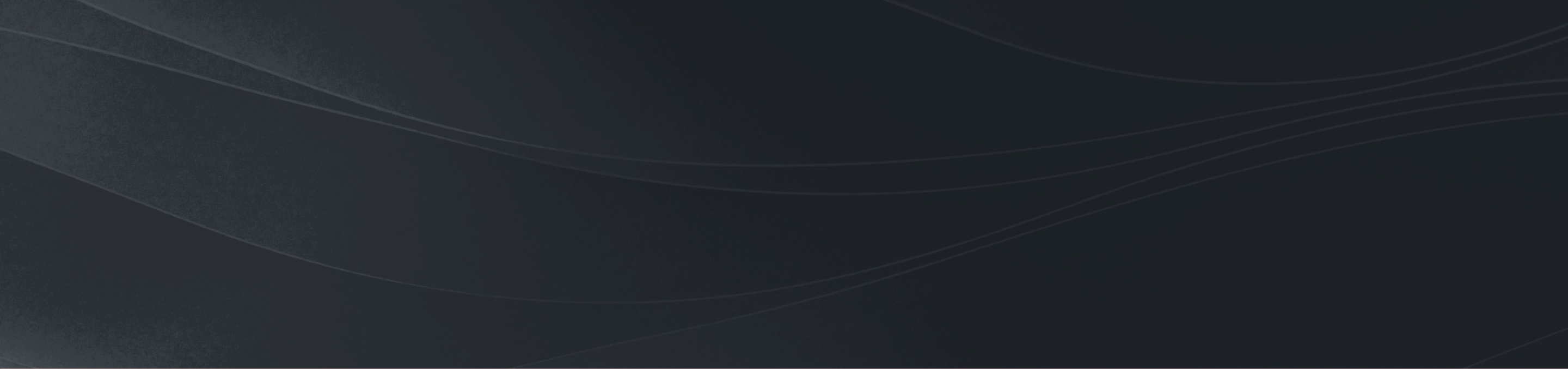

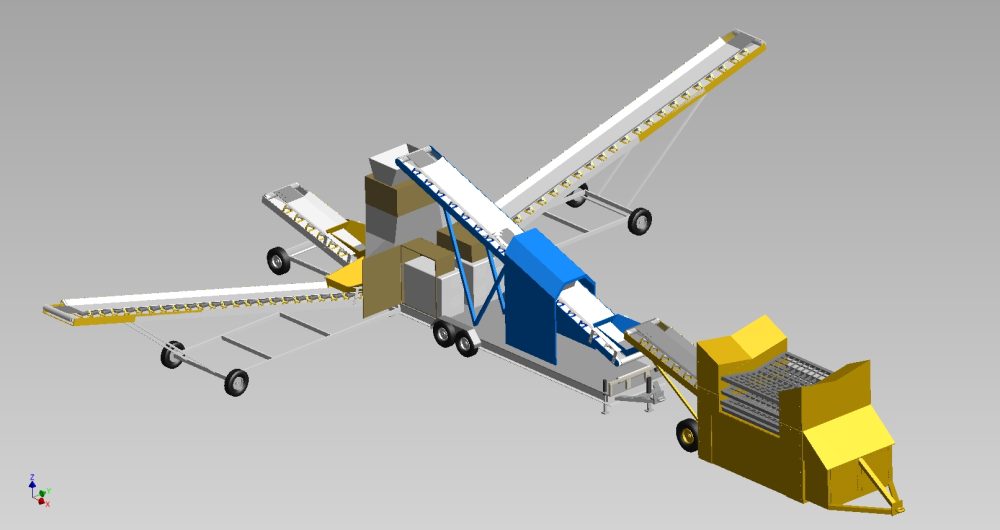

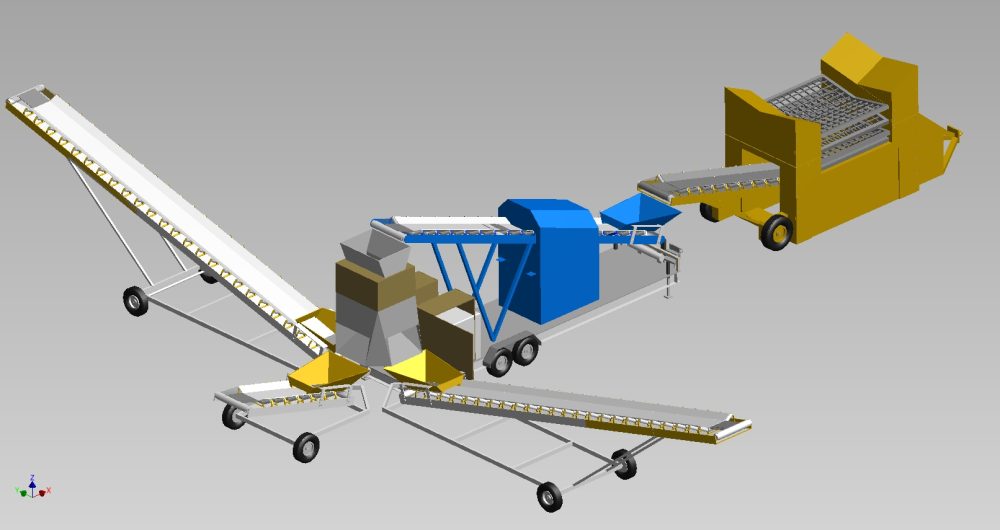

In a single container or trailer mounted unit, the Soil Measuring and Segregation System combines a soil belt conveyor, a high efficiency shielded scintillation radiation detector, a soil diverter/sorter and all of the necessary motors, drives and control electronics to perform soil measurement and to control the soil diverter mechanism. The system can be controlled via a PC

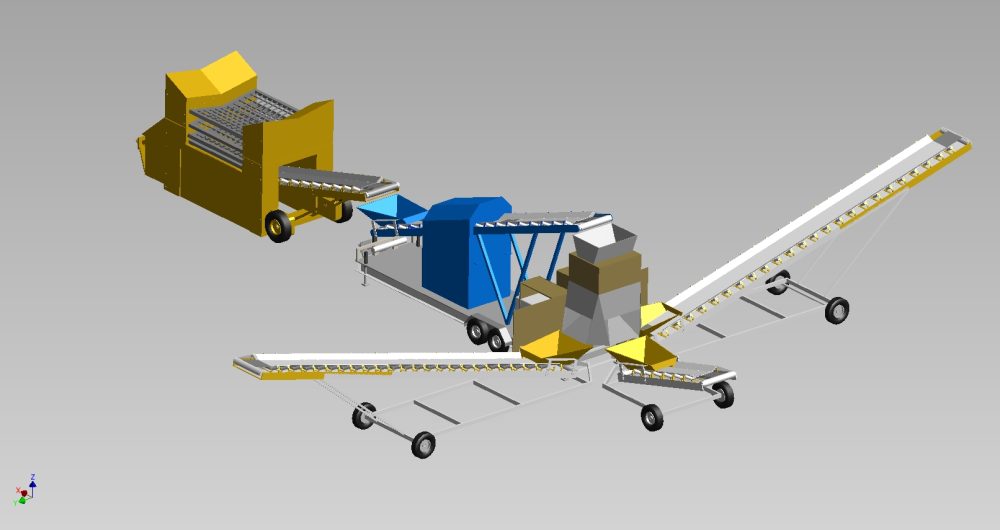

from a local control panel or over a remote link (Ethernet).Typically, after a radiological survey has identified areas with radioactive contamination at a site, the contaminated soil is excavated using suitable earth moving and excavation equipment, such as a front-end loader. The soil is transferred to a soil screening machine where the soil passes through a screen that removes oversized objects and stones. An output conveyor

on the screening machine feeds the soil or rubble to the input hopper of the SMSS. In some circumstances a conventional soil drying or shedding plant may also be required to prepare the soil before soil measurements are performed. Note that the excavation equipment and screening machine are provided by the customer and are not part of the SMSS supply. They are

standard gravel or soil handling equipment and are normally rented from local suppliers.Soil that has been screened arrives at the input hopper of the SMSS and is levelled to a fixed depth on the conveyor belt. It then passes under the high efficiency scintillation radiation detector, which is optimised to detect particular radionuclides. Depending on the radionuclides detected and the measured activity, the microprocessor controller diverts a volume of soil on

the conveyor based on the sorting criteria.The soil diverter or sorter comprises an input-hopper, a motor driven rotating inclined chute and 3 fixed and enclosed output chutes. The output chutes are normally aligned with the input hoppers of up to 3 conventional soil elevator or stacker conveyors (typically rented for the project from a third party supplier) which transport sorted and segregated soil to its various destinations. These destinations could include a stockpile, filling a vehicle (dump truck) or filling a 1m³ material handling bag.

The separated contaminated and uncontaminated soil outputs are either stockpiled for later disposal or loaded directly into vehicles for backfill or off-site disposal (in the case of contaminated soil). The measurement cycle may be repeated to further optimise the segregation

-

Specifications

Detector4" x 2" x 16" Sodium Iodide DetectorDigital MCAOrtec digiBASEAnalysis SoftwareANTECH SpectrumAnalyserThroughput55m³/hr typicalDetection Limit2.7 pCi/g (0.1 - 1.83 Bq/g) (typical)