The ANTECH Passive Neutron Drum Monitor is a comprehensive measurement system for the determination of plutonium mass in intermediate, transuranic or low level waste using passive neutron total coincidence or multiplicity counting.

- Passive neutron coincidence counting with a suitable calibration

- Absolute passive neutron multiplicity assay (independent of sample matrix and without calibration) for appropriate PCM waste streams and sample types (M=1)

- Suitable for PCM waste with a high alpha ratio (alpha<10)

- Optimised for use with the ANTECH N2000 Series Universal Neutron Counter.

- N2000 Input provides individual totals count and statistical analysis for each of the 16 counting chains (each chain has a separate head amplifier).

Benefits

- High detection efficiency for coincidence and multiplicity counting with low background polyethylene shielding

- Semi-automatic drum loading and unloading

- Automated measurement procedure employing user friendly Windows based Neutron Coincidence Counting and Neutron Multiplicity software incorporating an analytical dead-time correction

- Instrument normally supplied with the ANTECH N2000 UNC with multiple gate neutron coincidence plutonium analysis software with including wide range calibration function

- ANTECH A2000-15 TTL-LVDS convertor

Features

-

Description

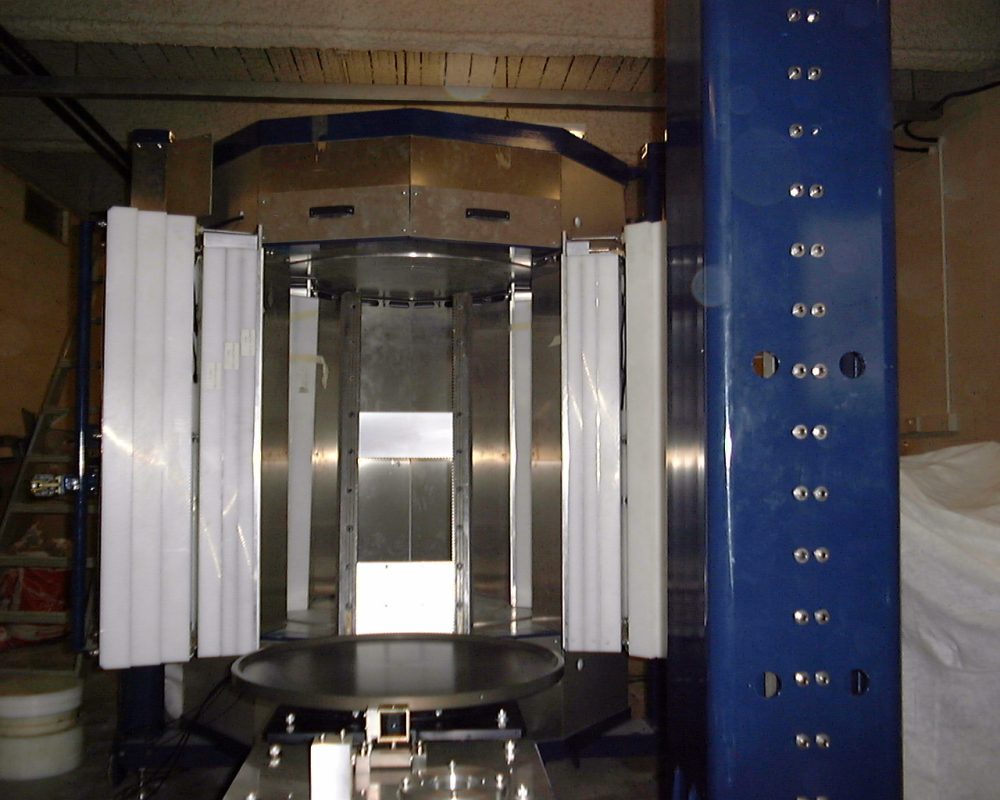

The User Software controls the semi-automatic loading of 220 litre (55 gallon) drums and the neutron data acquisition and analysis algorithms. The instrument determines the Pu-240 effective mass (²⁴⁰Pueffective) and this data may be combined with Pu isotopic ratio data (from mass or gamma ray spectroscopy) to determine the mass of all of the individual plutonium isotopes. The neutron drum monitor can be integrated with a high purity germanium (HPGe) gamma ray drum scanner for plutonium isotopic ratio determination. Using, for example the PC/FRAM, MGA or other isotopic analysis code (see Passive Neutron and Gamma Drum Monitor).

The neutron detection system is based on 16 rectangular polyethylene modules. Each of these modules contains eight ³He tubes that are connected to a high voltage junction box. Each junction box contains an Amptek charge sensitive amplifier/ discriminator circuit and connections for high voltage, low voltage and signal cables. The detector modules are housed inside a 210 mm thick polyethylene outer shield that is covered in stainless steel. The internal and external module surfaces are covered in cadmium to absorb re-entrant thermal neutrons. This cadmium liner can be removed to increase the detection probability for coincidence and total neutron counting.

Drums for measurement are loaded manually (drum lifter or forklift) onto a drum carrier which moves on slide rails. A drum is loaded into the measurement chamber in the following automatic sequence:

1. The Drum Monitor doors are opened using automatic linear actuators;

2. A slide rail “drawbridge” is automatically lowered into position linking the external slide rails on which the drum carrier sits to slide rails in the measurement chamber;

3. The drum on the drum carrier is moved into the measurement chamber by an electric motor driven “engine” which uncouples the drum carrier;

4. The drum on the carrier remains in the chamber and the “engine” withdraws to its original drum loading position external to the measurement chamber;

5. The slide rail “drawbridge” is automatically raised to its original position out of the chamber and clear of the doors;

6. The Drum Monitor doors are closed and the neutron measurement starts.This basic design is flexible and can be modified to fit specific requirements: the number of tubes may be increased (to increase counting efficiency), the moderator thickness may be adjusted (to vary the shielding and die away time), and lead shielding may be added (for the measurement of gamma ray active waste) see also the High Efficiency Passive Neutron Drum Monitor. The Passive Neutron Drum Monitor is optimised for use with the ANTECH N2000 Universal Neutron Counter (UNC). The N2000 provides data acquisition for both neutron coincidence and neutron multiplicity counting, as well as total neutron counting.

For pair correlation counting in neutron coincidence mode the frequency histogram collected by the N2000 is used to generate the ‘Reals’ coincidence rates for each of the 16 modules. Each ‘Reals’ rate can be used with a multi-gate calibration function to determine the ²⁴⁰Pueffective mass from the total plutonium mass. For a wide range of Plutonium Containing Materials (PCM) such as PuO2 and PCM with unitary neutron multiplication (M=1), triple neutron correlation may be used in absolute multiplicity counting mode. In these cases total plutonium mass and ²⁴⁰Pueffective mass are determined without the use of a calibration function and the matrix characteristics are determined from the measured detection efficiency.

-

Specifications

Neutron Detector64 Cd shielded ³He detector tubes, 25.4 mm x 1000 mm at 5 atmospheres 1" diameter, 39.4" longDetection Efficiency20%Measurement Time20 minutes per drum typicalDie Away Time68 msSensitivityEstimated sensitivity at sea level for multiplicity counting (n triple correlation)

50-100 mg ²⁴⁰Pueffective (Cd liner fitted)