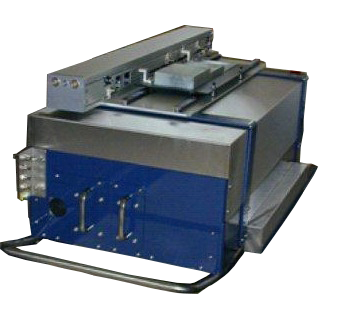

The ANTECH model G3651 Fuel Element Debris (FED) Monitor is a heavily shielded and collimated far field measurement instrument originally designed for the measurement of highly radioactive fuel element components and debris from UK MAGNOX reactors.

- Higher gamma ray energy resolution using an HPGe detector provides better precision for the detection of fuel element fragments

- Electromechanical cooling of the HPGe detector eliminates the need for liquid nitrogen (LN2)

- Stainless steel filters extend the dynamic range of measurement to higher gamma ray dose-rates

Benefits

- 30% heavily shielded and collimated HPGe detector in Far Field geometry

- Inverted pyramid tungsten collimator, set into the lead shielding

- Automated stainless steel filters of different thickness (0, 24, 42 and 56 mm) to attenuate high dose-rates

- Full spectrum 16k multichannel analyser (MCA) based on the ORTEC DSPEC PLUS provides high count rate capability

- Electromechanical cooling of the detector using the ORTEC ICS

- Electronics including the controlling computer, MCA and electromechanical cooler located remotely from the monitor in a low radiation background area

Features

-

Description

is highly radioactive, remote handled (RH) solid reactor fuel intermediate level waste (ILW). The monitor is designed to measure 137Cs in the presence of 60Co from mnemonic springs. The nominal design activity for 60Co in 50 litres

of FED waste (excluding abnormal items) is 5.6 x 1010 Bq (1.5 Ci) although the total design activity is much greater when considering the significant presence of 137Cs in the waste. The monitor is designed to detect fuel fragments that may be in the FED from the associated high level of 137Cs in a background of gamma rays arising from 60Co. With a very high Compton scattering of gamma rays in the waste the detector is not able to resolve any radionuclides much below the energy of 137Cs (662 keV).The G3651 consists of a 30% high purity Germanium (HPGe) detector with electromechanical cooling, avoiding the use of liquid nitrogen (LN). The HPGe detector and tungsten collimator is positioned in the centre of a substantial lead shield weighing nearly a ton. The detector and lead shield assembly moves on rails and, for MAGNOX FED measurements, is located in a shielded cave behind a shield door. For maintenance in this configuration the shield door can be removed and the G3651 FED Monitor can be moved manually out of the cave.

A tray containing the FED to a depth of 100 mm is viewed from below by the HPGe detector through an inverted pyramid tungsten collimator, set into the lead shielding of the G3651. The tray containing the FED is positioned above the detector and shield with a separation of typically 1.2 metres. A contamination barrier is positioned between the FED tray and the shielded detector assembly. A small area on the side of the HPGe detector crystal looks up through the inverted pyramid collimator with a field of view such that it sees the entire area of the tray. A series of stainless steel filters of different thickness (0, 24, 42 and 56 mm) move automatically on slide rails on the top of the shielded detector assembly and they can be positioned in front of the collimator aperture, depending on the count rate seen by the detector.

An electronic rack, which forms part of the G3651, is normally located remotely from the shielded detector in a low radiation background area. It also contains the power supplies, the controlling computer and the electromechanical cooling for the detector based on the ORTEC ICS. It also houses the 16k multichannel analyser (MCA) based on the ORTEC DSPEC PLUS and the control electronics for deployment of the automated stainless steel filters.

User-friendly Windows based software controls the monitor including the deployment of the stainless steel filters and analyses the measurement data.

-

Specifications

Gamma DetectorGEM30 P4, ORTEC ‘Pop-Top’ HPGe detector with head amplifier.

30% efficiency (others available on request)Measurement TimeTypically 10 minutes per trayNominal Design Activity60Co in 50 litres of FED - 5.6 x1010 Bq (excluding abnormal items)

137Cs in 50 litres of FED - >3.7 x 1011 Bq 1.5 Ci 10 Ci